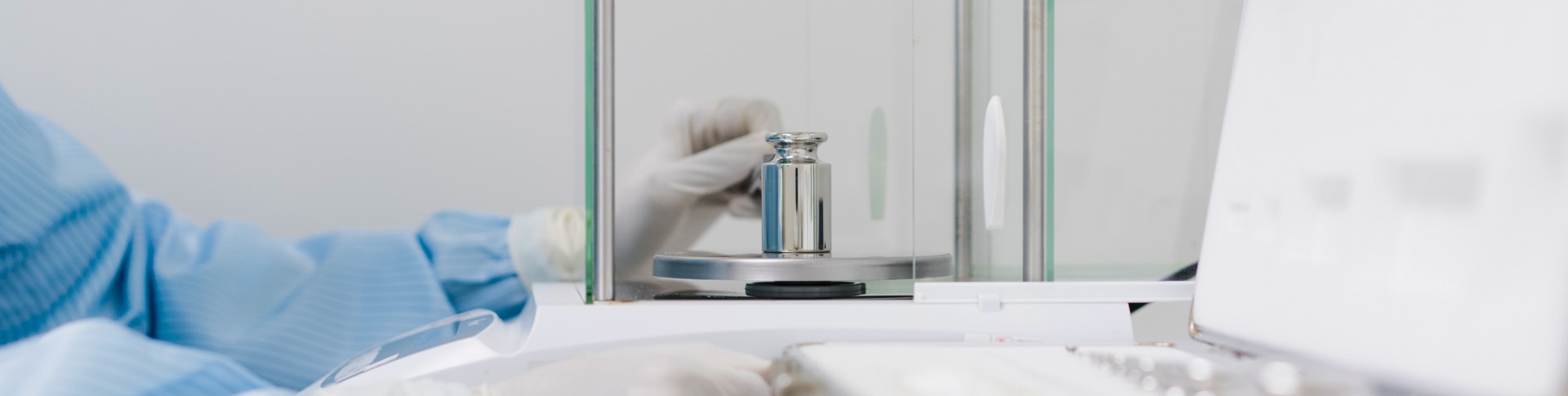

Calibration - measuring quality

Most major industry regulation authorities, such as the HPRA and FDA require that manufacturing equipment is maintained to the highest standard by a routine maintenance schedule. Calibration of instrumentation and execution of preventative maintenace routines are key to ensuring accuracy and compliance.

Calibration is the comparison of measurement instrumentation readings to a calibration standard of known accuracy. Using traceable reference standards we aim to provide a 4:1 accuracy ratio for all our calibrations between the reference standard and the device under test.

As almost all instruments will drift over time as a result of normal wear they will require regular calibration. Some equipment will drift less than others but regardless of drift tendencies, it is important that calibrations are performed in order to ensure the quality and integrity of manufactured products and confirm that all systems are reliable and accurate to ensure compliance.